Stainless Steel Tanks

Stainless steel tanks are available both in standard and/or customized configurations, as per specific needs, with several optional accessories as nozzles, manholes, sampling valves, instruments, covering and thermal insulation.

Stainless steel tanks -- each size, from the smallest to the biggest one -- are on-site manufactured. Multiple accessories are available as heating or cooling jackets, mixing stirrers, sampling valves and so on. Customization are made under client's needs depending to application and different areas of use (Chemical, Pharmaceutical, Wine or Food apps). Our background allows to manufacture products with high standard levels, taking care of costs as well with the right balance in between. Too low prices always hide something wrong, i.e. doubts in the quality of raw materials, inadequacy on certificates of origin, not a state-of-art in weldings, lack of documentation and poor technical support.

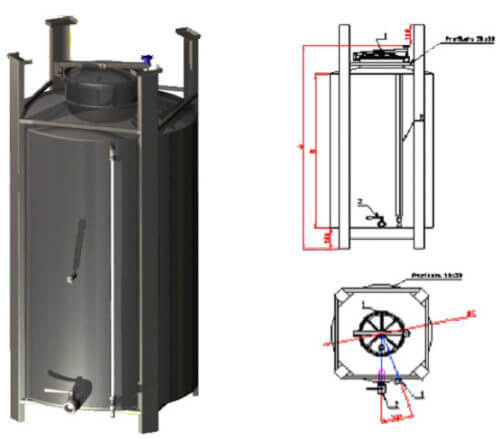

Palletized Containers

Palletized containers are manufactured in stainless steel only, to guarantee chemical compatibility with a wide range of products. Those containers can be supplied in compliance with ADR-RID UN 31 AY requirements for dangerous goods, after to be undergone to specific stress tests, with issuing of inherent certificates as well. The tanks are produced in series and also can be fitted and equipped according to the needs of production, storage, handling and transportation.

- Standard - transport and storage of liquids or powders

- Special - customized on costumer's request.

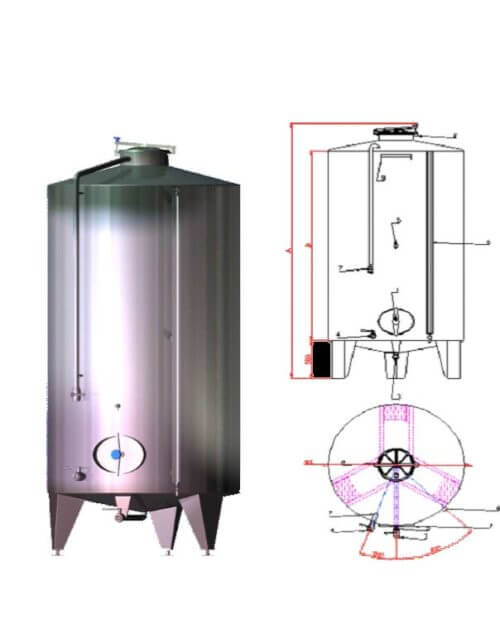

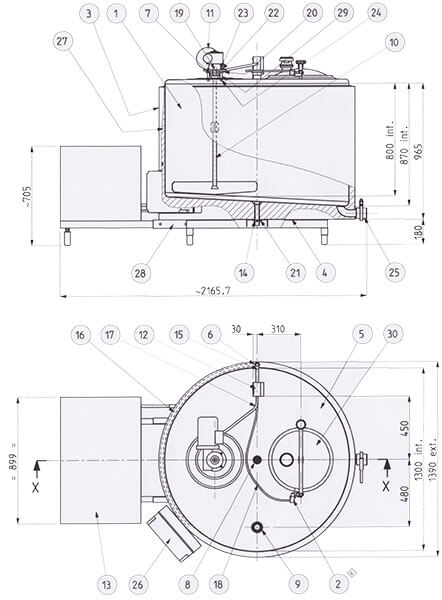

- 440 x 320 elliptical band (from 20 hl onwards);

- F4 top catcher, with double-acting vent valve;

- Partial load F;

- Total load F;

- Tap picks sample;

- Level auction with reg.liv.inf. and sup .;

- Rest scale;

- Stainless steel feet H: 450 mm adjustable (from 20 hl onwards).

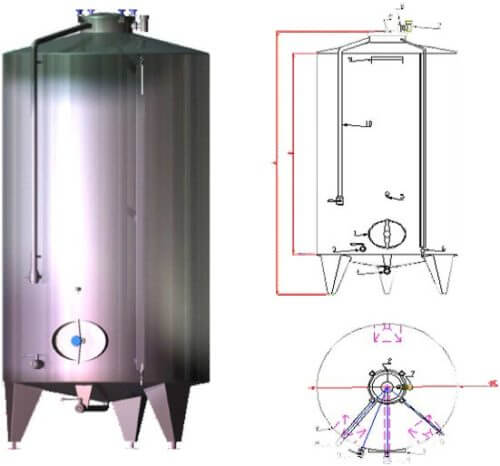

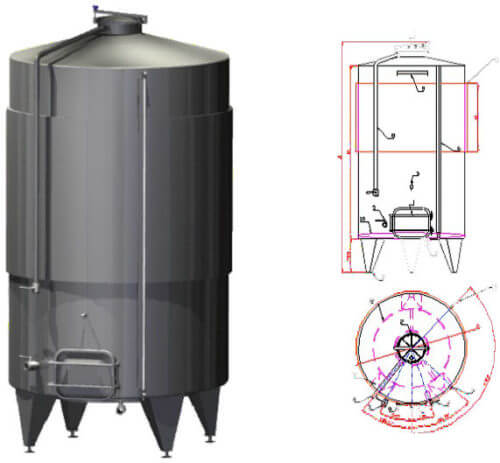

- 440 x 320 elliptical band (from 20 hl onwards);

- F4 4-spoke upper basket;

- Partial load F;

- Total load F;

- Tap picks sample;

- Level auction with reg.liv.inf. and sup .;

- Nitrogen safety valve 20 mbar;

- Rubber attack F 16;

- Scale up;

- Stainless steel feet H: 450 mm adjustable (from 20hl onwards);

- Flag device;

- Floating with food seal;

- Winch (from 30 hl onwards);

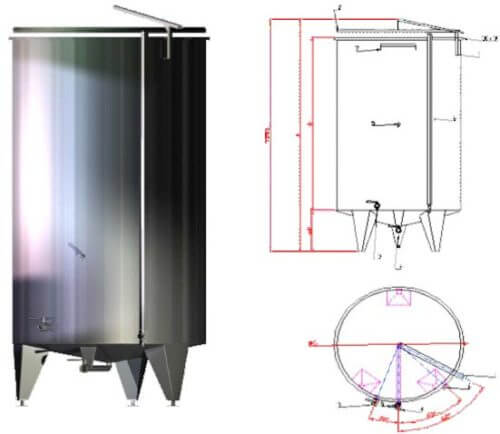

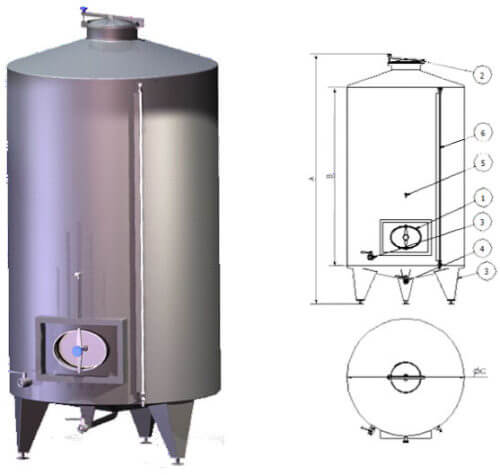

- Partial load F;

- Total load F;

- Tap picks sample;

- Level auction with reg.liv.inf .;

- Reggi scale;

- Stainless steel feet H: 450 mm adjustable (from 20 hl onwards);

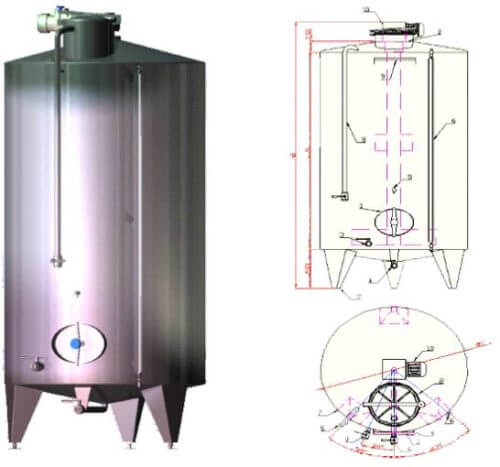

- 440 × 320 elliptical door with safety microswitch;

- F 400 circular cover, with polyethylene breather valve;

- Partial discharge F;

- Total exhaust F;

- Cock picks sample;

- Level auction with reg.liv.inf. and sup .;

- Stainless steel feet H: 600 mm adjustable (from 20 hl onwards)

- Loading tube * from F1;

- Scale up;

- Slow revolving motor-driven mixer (optional with inverter);

- Top dough cover F 400, with double-acting vent valve (F 300 for 2hl);

- Total exhaust valve F;

- Level auction with reg.liv. lower and upper, metric rod, Plexiglas rod

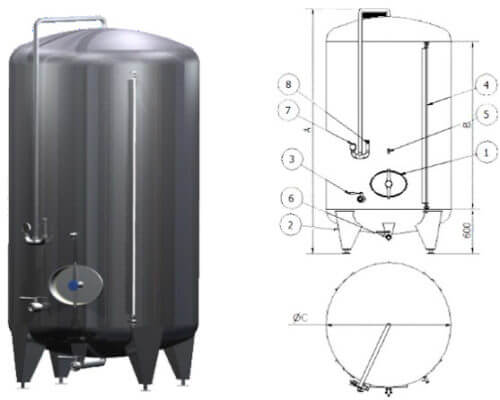

- Rectangular tray 550 x 440 with external opening (440 x 320 up to 50 hl);

- Circular fastener F 400, with double-acting valve;

- Partial load F;

- Total load F;

- Cock picks sample;

- Level auction with reg.liv. Inf. And sup;

- Stainless steel feet H: 500 mm adjustable (from 20 hl onwards);

- Process fluid connections 1 “+1/4;

- Reggi scale;

- 4% pendant floor;

- Insulated refrigeration compartment 25mm insulating thickness;

- Stainless steel analog thermometer with cockpit;

- Stainless steel well for PT100 thermometric probe;

- Reassembly hose * F1;

- 440 x 320 elliptical hatch with insulated hatch cover (from 20 hl onwards);

- F 400 circular cover, with double-acting relief valve;

- Partial discharge with valve F;

- Total exhaust with F valve;

- Cock picks sample;

- Level auction with reg.liv. inf.e sup.asta plexiglass;

- Stainless steel thermometer with cockpit;

- Refrigeration pocket on planking and bottom;

- Stainless steel feet H: 450 mm adjustable (from 20 hl onwards);

- Process fluid connections 1 “+1/4;

- Total insulation of the entire thickness tank max 50 mm;

- Thermowell and thermometric probe;

- 440 × 320 elliptical door with internal opening;

- Feet stainless steel with register

- Partial discharge with valve F;

- Total discharge with F valve;

- As level with upper level supports and inf;

- Tap picks sample;

- Pressure gauge 0-10 bar;

- Safety valve;

- Cooling unit

- Stainless steel washing ball

- Ventilation and drain appropriately sized

- Anti-foam load

- Dial thermometer

- Float level indicator

- Electro-agitator with stainless steel agitator blade shaft